Our Path Toward Climate-Friendly,

Fully Automated Production

An Industry Reinventing Itself

The production of recycled rubber products has traditionally been a low-margin business. One key reason is that comparable virgin-material products with similar performance have long dominated the market and were favored by consumers. Virgin materials were associated with innovation and quality, while recycled products were viewed as niche solutions with limited relevance.

A clear shift began with the EU’s output-oriented Waste Framework Directive of 2018. At Gum-tech®, we followed this development closely—not only through the EU’s circular economy packages, but also through a noticeably growing interest among our customers. Today, demand is rising across the safety flooring, fitness, and sport-surface industries, and new application areas for recycled rubber are emerging rapidly. Political decisions in recent years have also marked a departure from waste exports and increased legal and financial support for the recycling industry.

If We Recycle, We Need to Do It Right

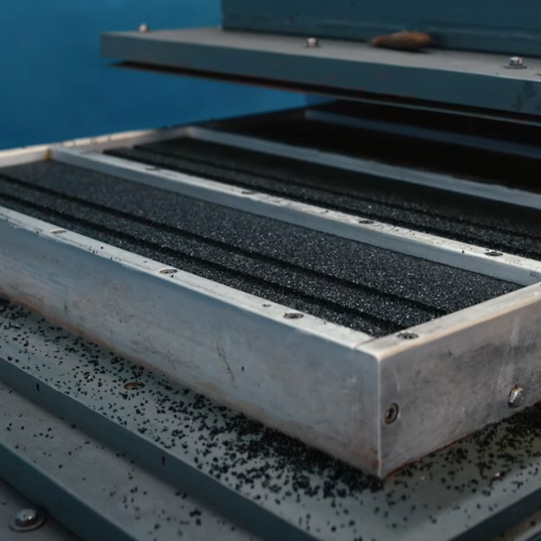

For decades, production technology in the recycled rubber sector barely changed. Large molds were filled by hand with granulate and then pressed under heat. At Gum-tech®, we want to push this industry forward rather than simply maintain old standards. Manually operated presses come with well-known challenges: inconsistent mold filling, incorrect binder ratios, irregular press times, and the resulting risk of production failure. Achieving consistent product quality under these conditions requires intensive monitoring and frequent sorting of defective pieces.

To increase efficiency and meet modern sustainability expectations, Gum-tech®—with guidance from the Green Choice expert advisory board—decided to fully automate its production lines. Our new 2024 automated Puzzle Mat 3D® press systems now reduce production waste by 70%, increase output stability, and significantly improve product availability for our customers.

Green Energy and Better Insulation

As the recycled rubber industry evolves into a showcase sector for sustainability, Gum-tech® incorporated energy efficiency directly into the construction of its new production facility.

Automation alone now saves approximately 30% in electricity consumption. In addition, a rooftop solar array supplies about half of the plant’s total energy demand. The new facility also features modern heat pumps and highly insulated halls, cutting heating energy consumption by around 50%, reducing both operating costs and CO₂ emissions.

Next-Generation Recycling Systems

The expansion of our automated machinery requires larger volumes of high-quality rubber granulate. For this reason, new shredding and recycling lines will be commissioned in 2024 directly adjacent to the production facility.

These systems are expected to double granulate output and give Gum-tech® full control over the quality and purity of its raw material. Securing a stable, high-quality feedstock is essential for consistently producing advanced recycled products and for developing new material innovations.

Disposal of Old Safety Surfaces

While we have explained how our climate-friendly production system works and how Gum-tech® maintains high quality while adhering to circular economy principles, one major question remained unanswered—by us and by the industry as a whole: What happens to old safety surfaces? How are Gum-tech® safety tiles treated at the end of their service life? Until now, we relied on external disposal companies. While these companies accepted the material, it was not always possible to verify whether the tiles were recycled, incinerated, or landfilled. Our new recycling systems change this completely. Gum-tech® can now guarantee that safety tiles from future installations—and even older existing projects being replaced—can be processed in-house, tested, and reintroduced into new products when material quality allows. This closes the loop and turns end-of-life tiles into a valuable secondary raw material.

Customers wishing to have old surfaces recycled at our facility are asked to ensure:

- professional packaging of the material

- recycling costs of €150 per ton

- transport to our production site